Grivel Turns 200 and Timeline of Innovative Gear

The Grivel name has had a strong connection to climbing for two centuries – both for the innate passion that has bound the Grivels to the mountains for generations and for the pioneering innovations of the equipment created by the skilled hands and ingenuity of the Grivels.

The skill and professionalism of the Grivel family are also evident in other activities that are now part of Courmayeur history, such as the historical sporting goods store called 4810 Sport, the new concept of ski rental/storage at Dolonne, the celebrated La Chaumière Restaurant directly on the slopes, cozy holiday rental apartments and the Val Ferret Fishing Club.

Over 200 years ago at the foot of Mont Blanc, in an area later called Les Forges, blacksmiths were busy making horseshoes, nails for boots and agricultural tools.

The water coming down from Europe’s highest mountains made the wheel of the first basic machinery turn.

In 1760, Horace Benedict de Saussure offered a money prize to the first to successfully climb to Mount Blanc’s summit.

On Aug. 8, 1786, Jacques Balmat and Michel Gabriel Paccard, both locals, laid claim to the prize by reaching the top.

Their climb included a forced bivy on the glacier, which disproved local legend that such a feat was not possible.

The first ascent marked the start of modern mountaineering and soon the need for specialized tools.

A few years later, the first blacksmith for Grivel was busy making shovels and hoes for working in the fields, locks for doors, horseshoes and nails for boots.

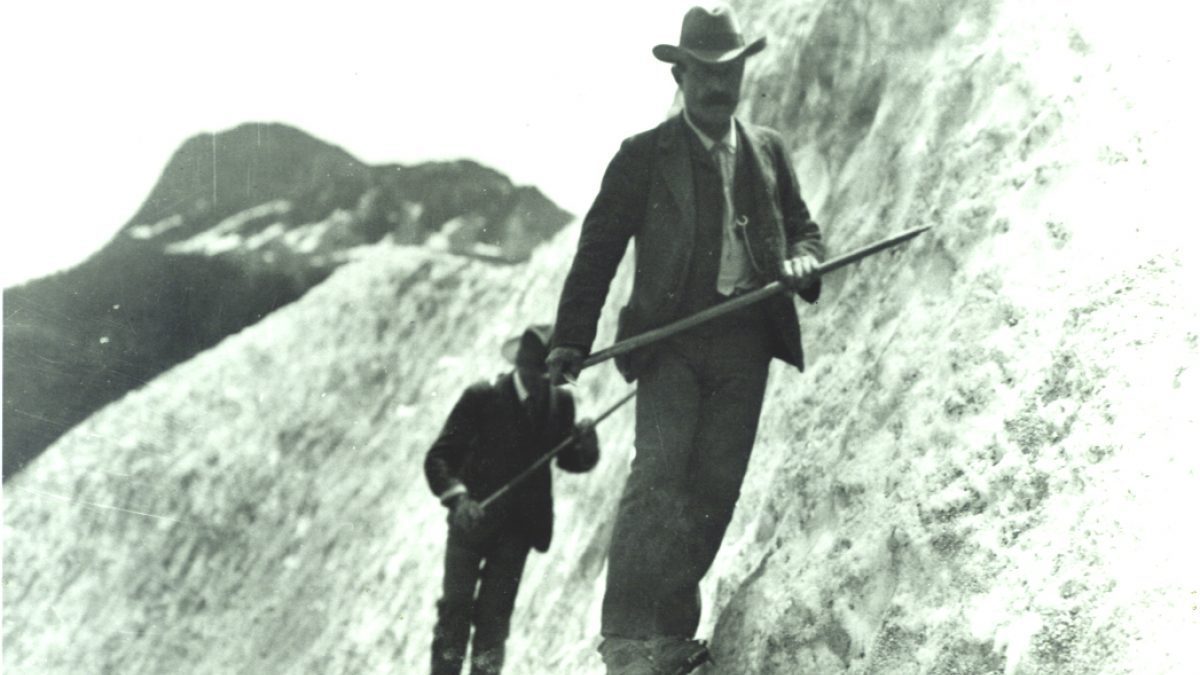

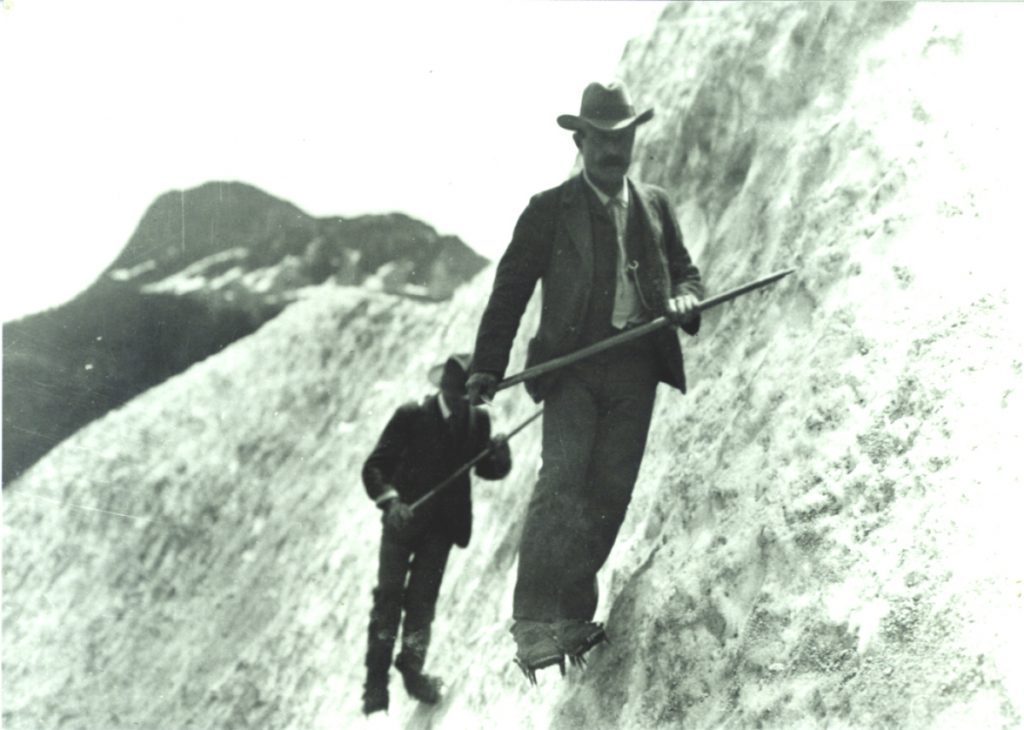

One day, a hunter was hired by an English tourist to take him to the top of a mountain. The hunter asked the blacksmith to make a different pick, something lighter and longer than usual, with a flat part to cut the ice.

And the first ice axe was born. Often they were modified agricultural picks.

There is little documentation around the time of Grivel’s founding, except for a cornerstone of the architrave in the workshop where the Grivels worked, which says 1818.

In 1871, sir Leslie Stephen said, “The first British travellers came to the mountains in the first decades of the 19th century with the intention of using them as a playground for a new sport: alpinism.”

In the following year, the blacksmith made many of them and improved the model. More and more wanna-be climbers started visiting the blacksmith to purchase the newly-made tools.

In 1909, The English engineer Oskar Eckenstein asked Henry Grivel to manufacture the first modern crampons. They dramatically cut down the time required to cut steps.

Then in 1929, Henry’s son Laurent made the brilliant invention of the two front points, allowing climbers to stand face on while climbing steep ice.

In 1936, Amato Grivel, Laurent’s younger brother, using the Chromolly alloy (nickel-chrome-molybdenum), created a much stronger crampon, which were not as thick and only weighed 360 grams a pair. They were called the Super Leggero Grivel and were later used to climb three of the highest peaks in the world: Mount Everest, K2 and Kangchenjunga.

Fast forward to 1993 when Grivel introduced the Rambo, a rigid crampon with a stable platform and no vibrations. Forged front points were added for the first time, a huge improvement.

Then in 1996, Grivel made the Machine ice tool. It revolutionized the design of technical tools. From then on, it was the shape that all manufacturers would use.

A few years later, Grivel made the Top Machine, the first tool without leashes. And they then came up with anti-ballers for crampons.

In 2010, Grivel installed a solar-panel roof and starting to produce its goods with solar energy.

In 2018, they’ll be hosting a 200-year anniversary party in Courmayeur and are releasing retro-gear. Thanks to Grivel for constantly pushing to improve how climbers move in the mountains.