Tommy Caldwell wants climbing to aim for a more sustainable future

From using less water to make ropes to not anodizing every carabiner, Edelrid is changing how we think about climbing equipment

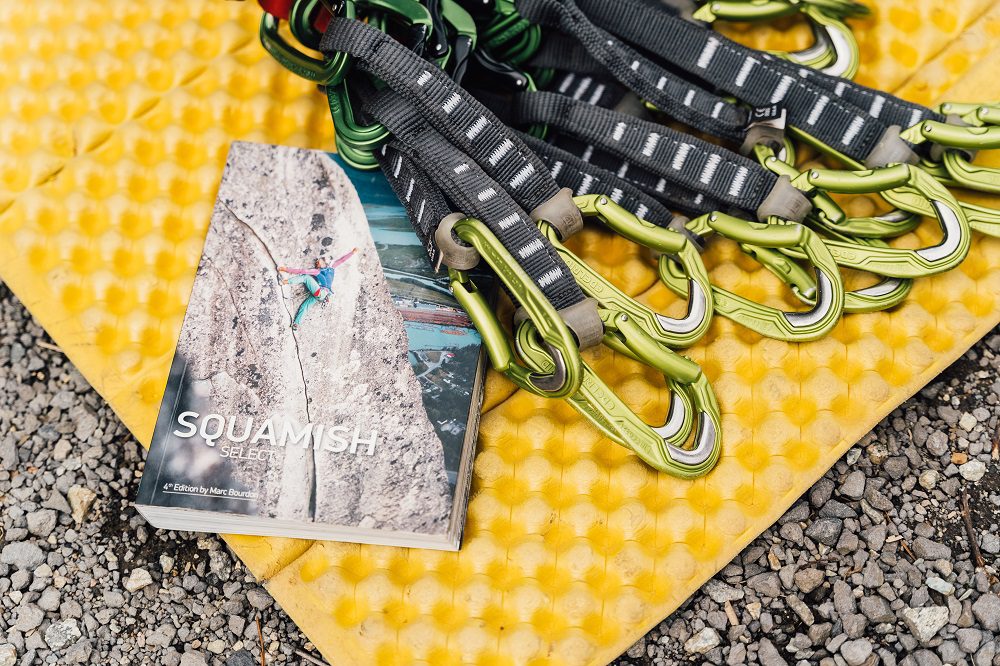

Beneath the granite walls of Squamish, a team of Edelrid stakeholders and designers gathered to share their vision of the future of climbing with the teams from the retailers Mountain Equipment Company (MEC). Edelrid wants to build equipment that doesn’t only last longer, but is less harmful to the environment than what’s currently available on the market.

Top climber Tommy Caldwell, known for his historic first ascents like free climb Dawn Wall and Flex Luthor, believes in the positive impact that Edelrid is having on the sport. He’s a part-owner of the North American distributor, and he came to Squamish to share his story.

“I met [Edelrid Brand Manager] Carsten von Birckhahn on a trip to Patagonia,” said Caldwell. “He owned a little house in El Chaltén that I ended up staying at. He had newly become the head of Edelrid, but I knew nothing about the company at the time.”

Caldwell said von Birckhahn approached him about the futuristic idea of climbing on 6 mm ropes. “He had ideas for systems that could legitimately change the way we move in the mountains today, ” said Caldwell. “So I got really excited about that. The idea of going and climbing big mountains with a 6 mm rope and these tiny little carabiners making your kit a third the size could really change things.”

In July, 2017, at age 49, von Birckhahn died in a paragliding accident in northern Italy. Caldwell said that they had become close friends after meeting in Patagonia.

“I started to get to know the company and they’re just so creative. Pushing it not only by innovating the equipment but innovating the supply chains and making things more sustainable and reducing the impact.”

Caldwell said that he started to look around with the companies that he already worked with. “The clothing companies are doing a pretty good job at finding ways to reduce their impact,” he said. “Food companies are doing great, but ropes and hardware – nobody was even talking about it before Edelrid.”

Caldwell, along with Blair Williams, now vice president of Edelrid North America, and a few others, decided, with von Birckhahn’s help, to start a U.S. distribution brand. “The goal has been to show the industry so that everyone starts to do better in terms of their environmental impact,” says Caldwell, “and I feel like it’s working.

“If you look at all the other rope brands, they’re all at least talking about it – there’s a fair amount of greenwashing, but they’re all at least talking about it now. So we’re making little steps.”

Edelrid was the first rope manufacturer in the world to ensure that all its ropes fulfil the bluesign environmental standard, creating a new benchmark for innovation. In 2015, Edelrid introduced the world’s first bluesign harness, the Huascaran. “At first, it was nylon products that seemed like the easiest,” says Caldwell, “because there are these big third party certifiers like bluesign. Edelrid changed their whole factory and started using way less chemicals and water.”

Vitus Wuhrer, head of purchase and supply, said, “Every product that we make should be as sustainable as possible. While oil-based products and metals aren’t green by nature, we’re constantly trying to figure out how to lower our impact.”

As Caldwell points out, “There aren’t always ways to make aluminum products more sustainable, or so I thought. But smart engineers at Edelrid starting coming up with ideas. They thought, we can’t really make aluminum less toxic, but what we could do, is make our belay devices out of steel, so that they don’t wear out.” Edelrid’s Bulletproof carabiners have steel inserts, making them last much longer than pure aluminum carabiners.

And there are more options, says Caldwell, like “simply not anodizing the carabiners, because you don’t really need anodized carabiners unless you’re going to leave them out in the elements the whole winter or climb on the ocean. Just figuring out how to skip toxic processes.”

More recently, Edelrid figured out how to melt down old ropes and make them into new ropes, helmet liners and plastic ice screw clippers. “They’re just figuring out ways to do it with all of their products,” says Caldwell, “which is cool because nobody else is really even trying.”

In 2023, Edelrid will introduce the first-ever bluesign certified helmet to the market, but more on that later.

And what happened to von Birckhahn’s idea of climbing with 6 mm ropes in the mountains? Caldwell tested the Edelrid Rap Line 6 mm Protect Pro Dry Rope and decided it was safe enough to use for climbing.

In summer 2020, Caldwell and Alex Honnold used one for their 40-kilometre 36.5-hour linkup of mountains in Rocky Mountain National Park they called the Continental Divide Ultimate Linkup or CDUL Traverse, which is pronounced “cuddle.”

Much like Caldwell’s visionary climbs, Edelrid’s innovations are building a legacy that will have a positive impact on climbers and the environment for decades to come.